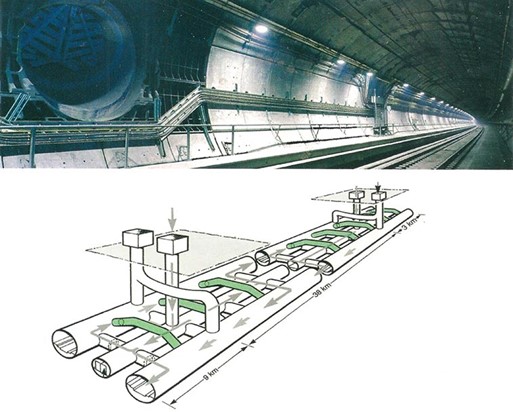

Rail Tunnel Ventilation is essential to remove the dangerous build-up of pollutants, reduce the risks of smoke during a fire and to remove the heat generated by the trains and other electrical equipment.

Virtually all of the electrical power consumed degenerates into heat which is removed by a combination of natural and powered ventilation. During free running conditions the piston effect of the trains may be sufficient for ventilation and natural ventilation may maintain this condition even when the trains are not operating. However, when the system becomes congested and trains are running at short intervals or, in the case of an incident, forced ventilation becomes necessary.

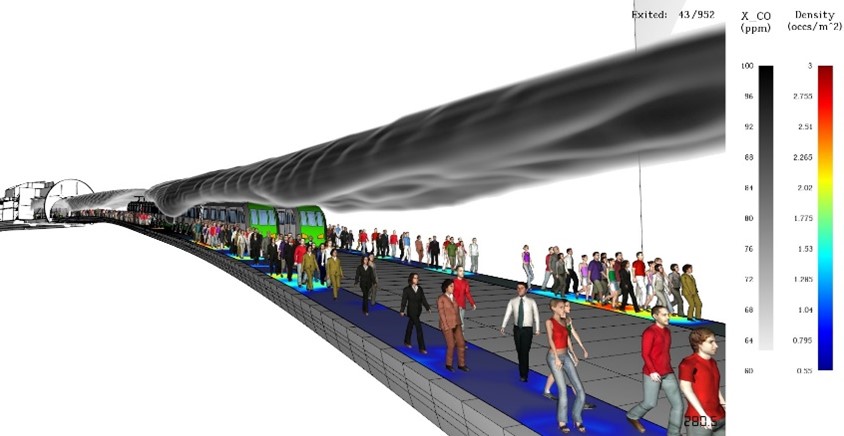

influx of a large number of people and the presence of moving trains generates a reduction of oxygen and an increase in heat and pollutant. Forced mechanical ventilation is then required to achieve the necessary air exchange and grant users of the underground train systems comfortable conditions. Ventilation systems have a second and even more important purpose. That is to guarantee safety in case of fire emergency. In order to create a safe and clean environment for escaping mechanical ventilation both in tunnels and in the stations is activated. In rails the ventilation of tunnels is mainly dedicated to fire emergencies where it is vital to keep under control the smoke propagation and create safe areas and clear environment for the users.

Usually, the amount of heat generated by trains in rapid transit systems of high-density usage is the largest single factor in determining the mass flow of air required to maintain a stable air temperature. However, the risk of fire must also be taken into account.

Longitudinal ventilation along the tunnel is common using 100% reversible fans. For an enclosed system large fan connected to atmosphere would be used in a push-pull configuration.

Smoke is directed in the most favorable direction depending on the position of a fire in the train or tunnel. Fans are rated up to 400 °C for 2 hours. Air movement in the stations follows normal ventilation practice as far as possible.

Metro and Rail Tunnel Solutions from Ecovent:

- Layout design for Energy Efficiency, Velocity Pressure effect & Acoustic Performance.

- Coordinated component effect on system

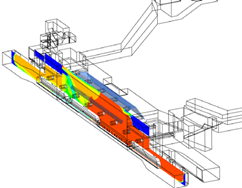

- Spatial Coordination using 3D Modelling

- Tunnel Ventilation Design & CFD Analysis

- SES Analysis

- Pressure Drop Calculations & Validation of Noise Calculations

- Factory Acceptance Testing

- Fan Installation Guidance & Commissioning Assistance

- Global Coverage & Support Service

- After Sales Support & Warranty

CE Marked Ventilation Products

Ecovent offers a wide range of CE marked EN12101-3 certified ventilation products.