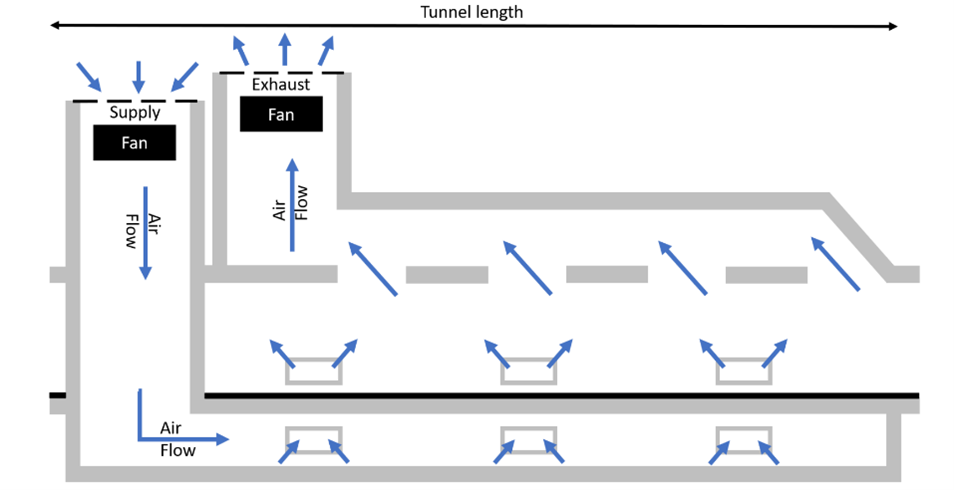

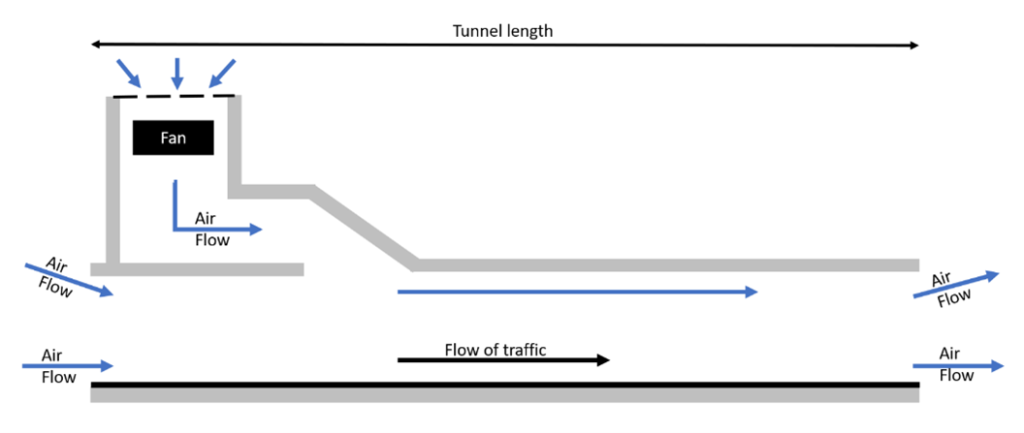

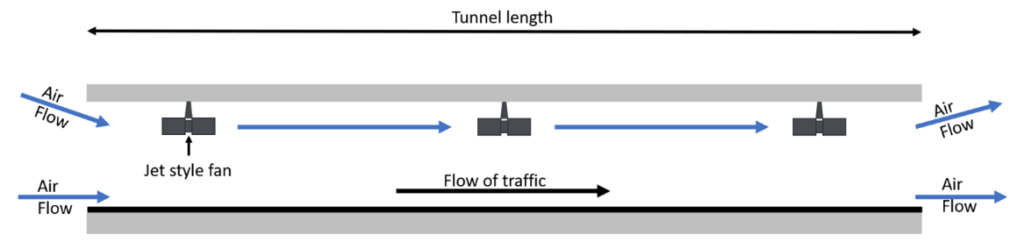

Road tunnel ventilation is required to prevent the buildup of vehicle exhaust fumes and maintain air quality for occupants. In road tunnels ventilation rates are needed to dilute the pollutant emissions from vehicles – like Carbon Monoxide (CO), Nitrogen Oxides (NOx) and soot (particles matter) – in order to keep acceptable air quality for the users.

Just as important is controlling the effects of a fire in tunnels. The ventilation system needs to be designed and sized to provide sufficient velocity and direction for controlling the spread of smoke and heat in the event of fire.

In the event of a fire this same system needs to be able to act as the smoke extract system allowing the tunnel occupants to evacuate and emergency services to reach the source of the fire and tackle it.

We can provide system design services and tailored products for: